Discover the Secret Behind Toyota’s Quality and Efficiency in the Only Lean Immersion Offered in Portuguese and Spanish at San Diego State University.

ACCELERATE 7 MONTHS OF RESULTS

From June 7 to June 13, 2026

See how much time is left until the event starts

THE TIME HAS COME FOR A TRUE TURNING POINT: THE ULTIMATE IMMERSION FOR LEADERS WHO WANT TO THINK LEAN FOR REAL.

Lean Immersion Week 2026 is not just an international training — it’s a true turning point for leaders who want more than mastering tools: they want to reprogram the way they think, decide, and act Lean.

Over seven intensive days at San Diego State University (SDSU), you’ll dive deep into the heart of Lean alongside those who carry Toyota’s original DNA — senseis and global experts who transform high-performance companies in the U.S., Brazil, Mexico, Europe and around the world.

It’s the only international Lean program offered in Portuguese and Spanish, featuring dual certification (SDSU + Honsha USA) and designed exclusively for professionals. Beyond knowledge, it delivers a profound experience with transformative dynamics, strategic provocations, and real-life simulations that pull you out of autopilot and reposition your mindset.

You’ll leave behind linear, bureaucratic, and reactive thinking — and switch to a new way of operating: strategic, lean, connected to real value, to your customers, and to the future. Here, learning is alive, practical, and accelerated.

Everyone is challenged to deconstruct old patterns and build, with their own hands, business and operational models that truly work.

Companies that have already participated.

TESTIMONIES FROM PARTICIPANTS OF LEAN IMMERSION WEEK

“Knowing cases from other companies, having close contact with people we didn’t know, that I didn’t know. This is extremely rich, extremely important.”

“Even with all my experience of over 14 years working with Lean, I learned new things from the senseis, like very specific nuances of Lean. I highly recommend it.”

“Learning from the senseis who worked at Toyota is amazing. In addition to networking and connecting with other people, I think it’s a great opportunity to truly immerse yourself. I highly recommend it.”

“I lived it, I experienced it, I had the opportunity and discussions. I can tell you: this immersion is real! It’s 7 months of learning in 7 days of immersion! It’s worth it!”

“Apparently complex topics are taught with a very simple and clear teaching method, accessible to anyone. We can see here that Lean is a philosophy for life and for living. I recommend it to anyone, in any position.”

“A unique opportunity to be with these Lean masters. We had many exchanges, and I leave here very enriched with knowledge, with my expectations exceeded. An experience I will carry for the rest of my life.”

“This immersion opened a new horizon for me, to go to the shop floor and better develop my work from now on. I feel more empowered to take on the challenge of building our area in a better way, in a leaner way. I invite everyone to take on this challenge.”

“My expectations for participating in this immersion were high, and now on the last day, I can say they have all been exceeded. The contact with the senseis, the exchange, the experience, all brought more knowledge to us. Truly a great event.”

“I learned that Lean is actually a way of life that I will carry not only into my professional life but also into my personal life. The great desire we have here is for everyone to have this experience. That’s why I highly recommend it.”

“I now understand why Toyota is what it is. The company’s president is here talking about what happens on the shop floor. For me, it was fantastic, emotional. I leave here a much more fulfilled person in terms of Lean. Thank you very much for the opportunity.”

“It was very important to participate in this immersion, and I leave here with a much broader view of Lean. It was far better than I had imagined, especially because of the program format, the group simulations, the visits, and the conversations with the consultants. The investment was definitely worth it.”

“This week with the senseis, who are the masters of Lean, surprised me in every way because we saw some of the theory at the foundation, but we also saw a lot of practical things, like the visits to companies here in the United States. I am extremely grateful. A unique opportunity. I recommend it to everyone who can come.”

WHAT IT’S INCLUDED?

Classes with the world’s leading Lean experts

Professionals and Senseis trained by Toyota

Intensive and interactive workshops

Guided visits to major American companies

Simulations and real-time learning

100% in-person in an immersive format

Exclusive classes in Portuguese and Spanish.

The international Lean training you needed

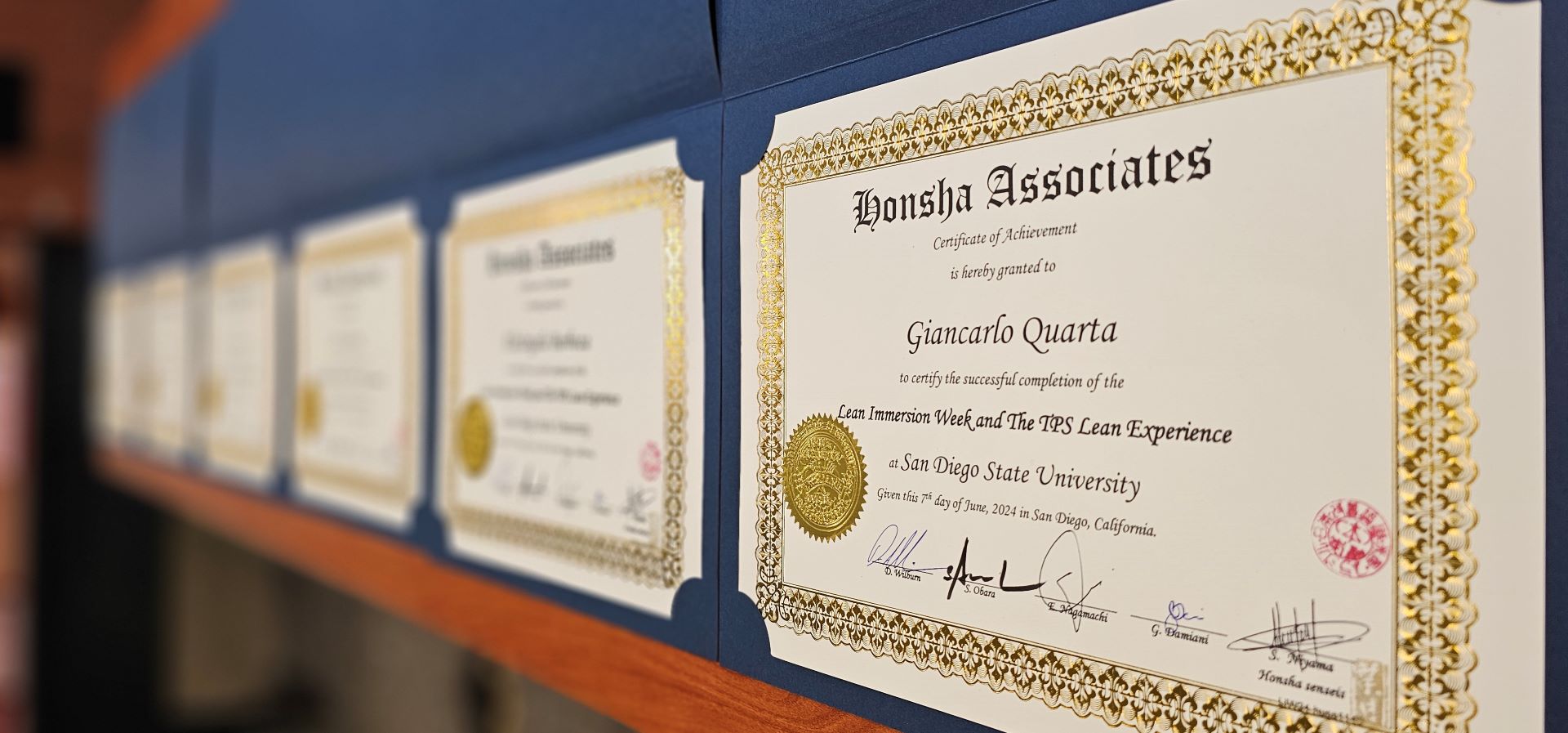

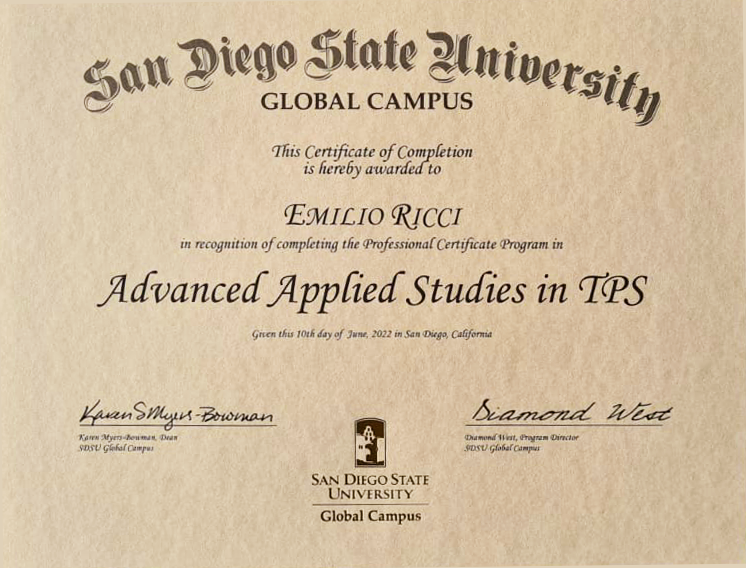

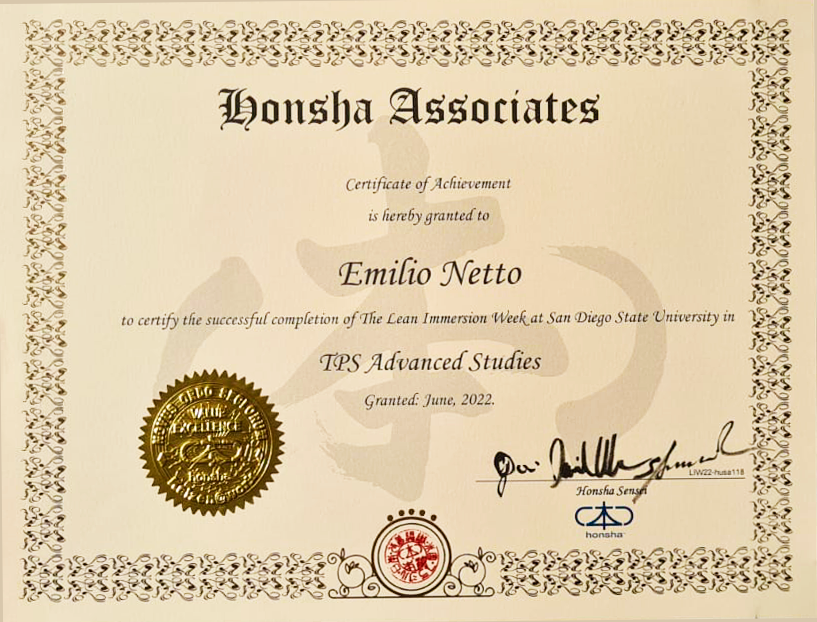

2 International Certificates: SDSU and Honsha USA

More than 45 hours of theoretical and practical activities

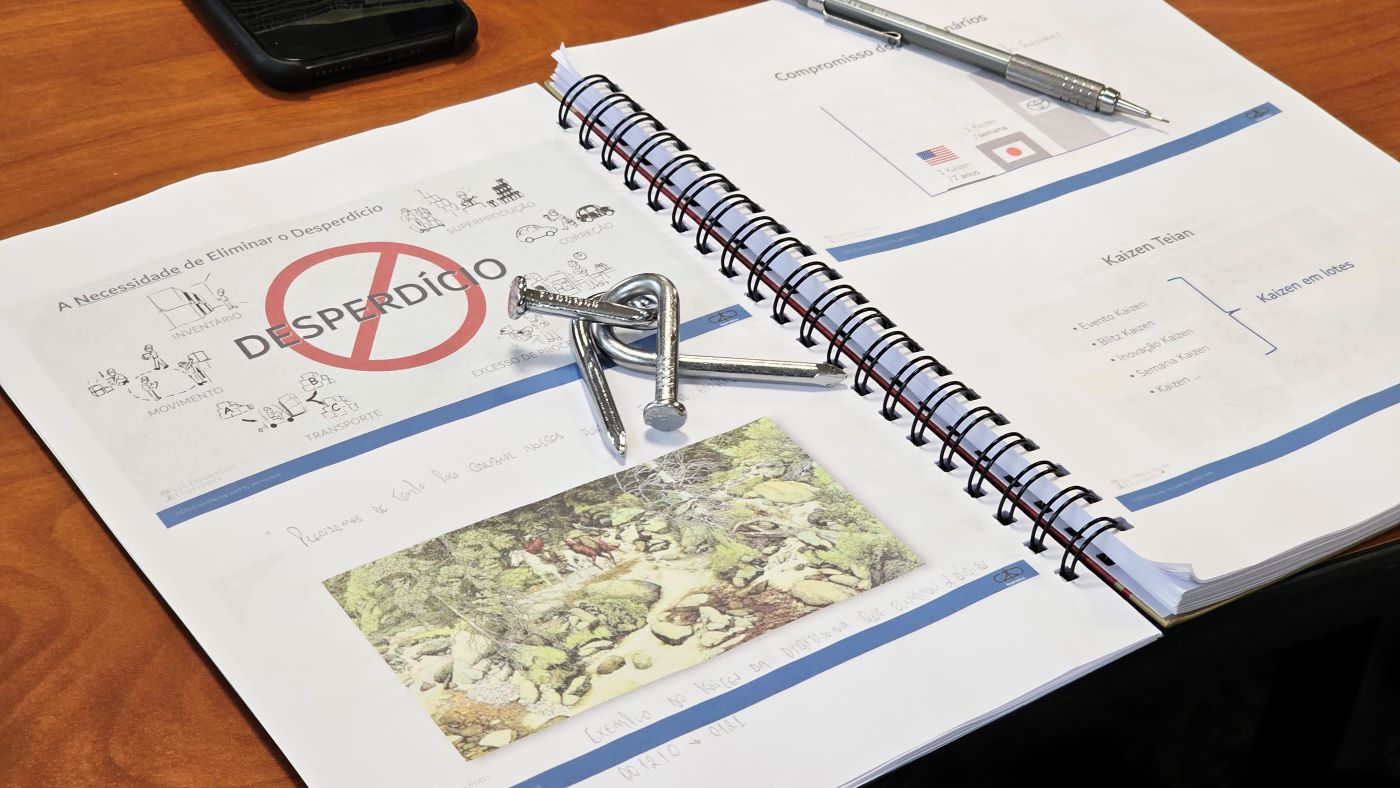

Printed and digital study materials

1-hour online mentoring session after immersion

WHAT’S ALSO INCLUDED

Private individual suite within San Diego State University

Ground transfers between airport-university and visits

Breakfast and lunch at the university’s restaurants

Free evenings for sightseeing and shopping

Mentorship with Honsha senseis after the event

Special event with welcome and graduation dinner

WHAT IS NOT INCLUDED?

Airfare, insurance, dinners, U.S. visa issuance, or any other items not mentioned above.

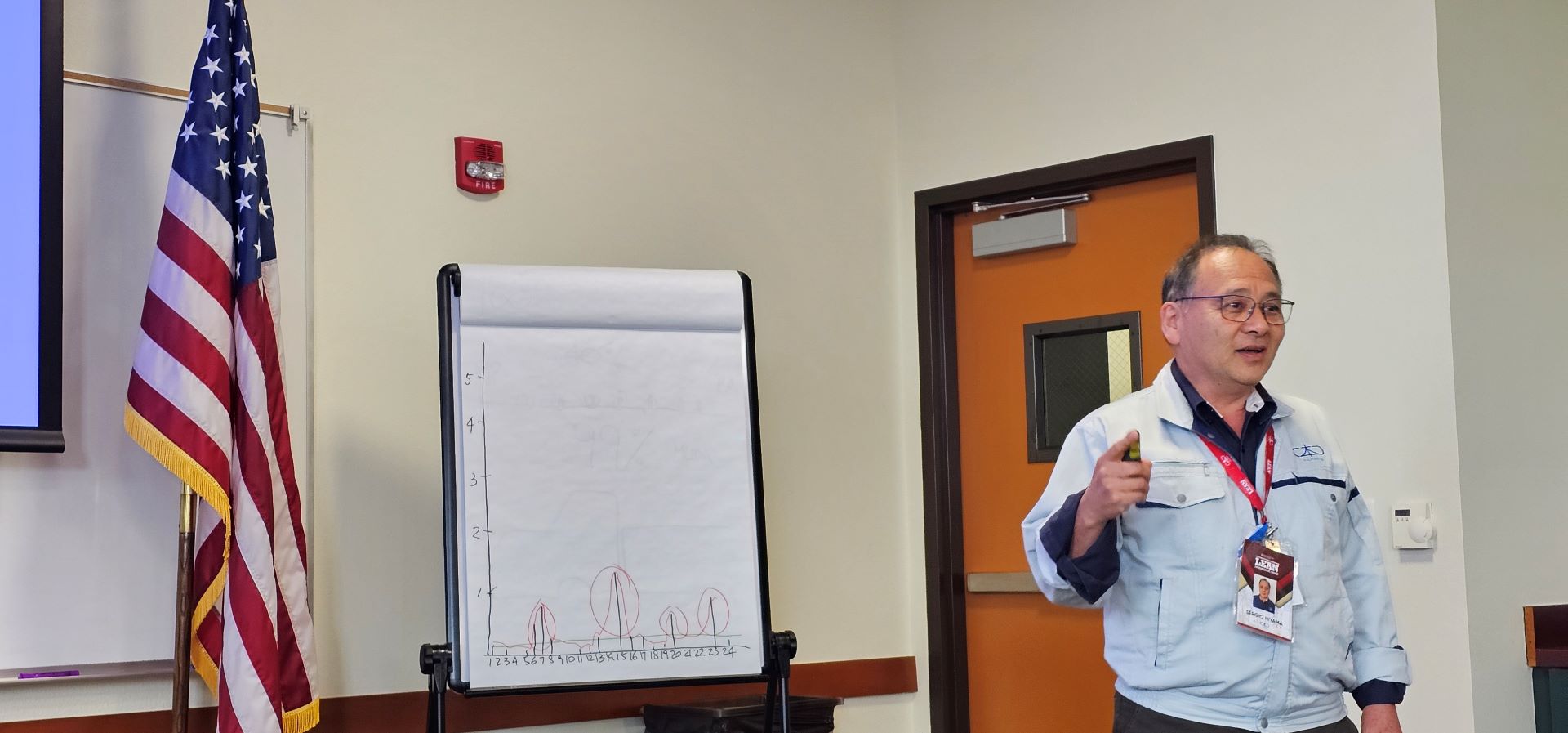

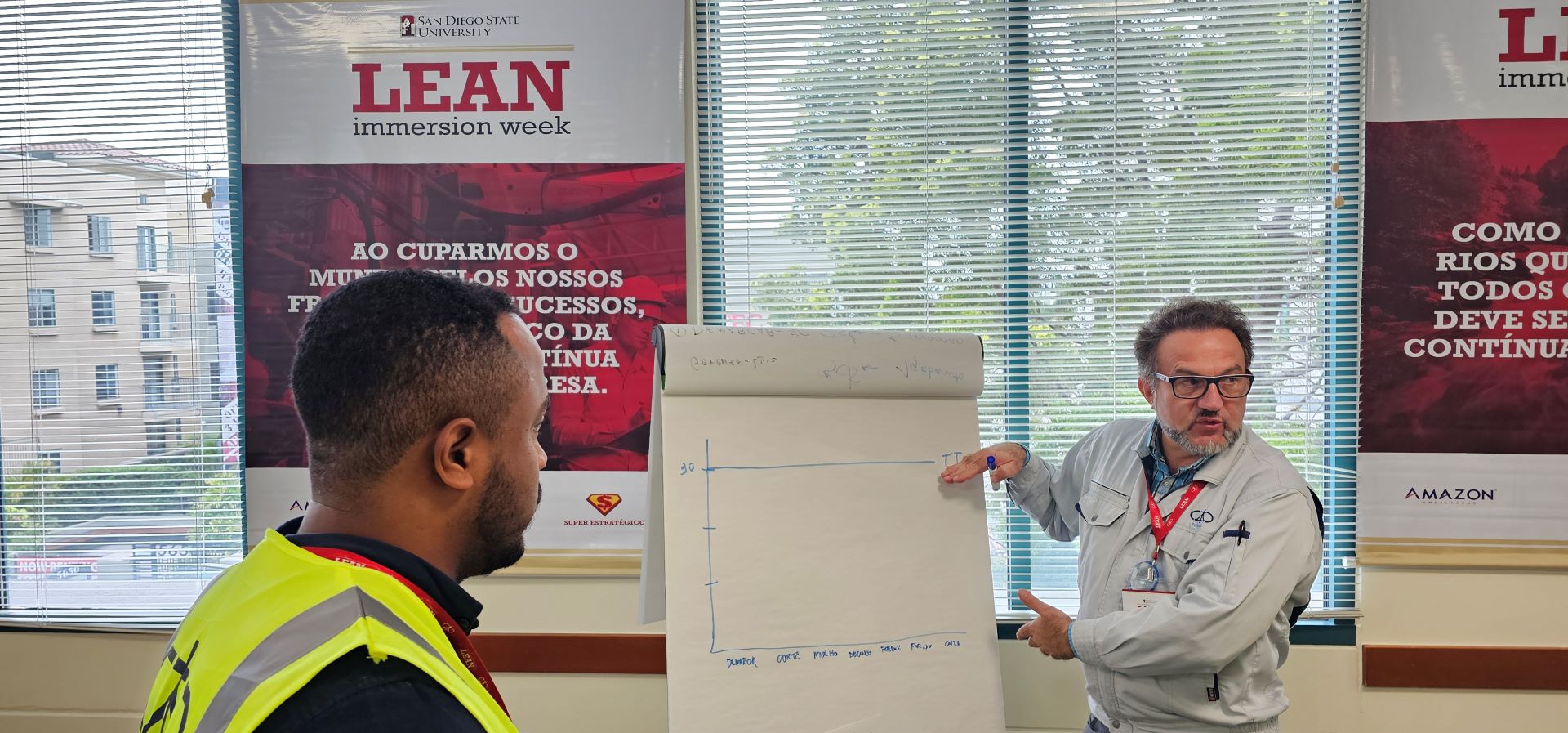

PHOTO GALLERY OF LEAN IMMERSION WEEK

CHECK OUT THE SCHEDULE

1st Day - June 7, 2026 (Sunday).

- .Welcome dinner and participant integration.

- Getting to know the activity schedule

2nd Day - June 8, 2026 (Monday).

Applied simulations and practice of concepts:

- 3D Lean Simulation

- Just in Time

- Kanban

- Jidoka

- Hoshin Kanri

- Yamazumi

- Standardized Work

- 5S

- Kaizen Teian

- PDCA/LBP

- SMED

- Assessment

3rd Day - June 09, 2026 (Tuesday).

Applied simulations and practice of concepts:

- Lean 3D Debrief

- Cultural Time: Differences between countries

- Testimonial from Brazilians in the USA

- The American Toyota

- Roundtable: Global experiences

4th Day - June 10, 2026 (Wednesday).

Guided visits to American companies that are highlights in the application of Lean methodology.

5th Day - June 11, 2026 (Thursday).

Guided visits to American companies that are leaders in the application of Lean methodology.

6th Day - June 12, 2026 (Friday).

Closing activities:

- A3 – Key learnings and main priorities to take home;

- Certificate presentation ceremony;

- Closing dinner.

7th Day - June 13, 2026 (Saturday).

Return Home

YOU HAVE A MEETING SCHEDULED WITH TRUE LEAN DNA TOYOTA SENSEIS.

samuel obara

Sammy learned and implemented the Toyota Production System (TPS) at Toyota facilities in Japan, Brazil, Venezuela, and the United States. He taught Lean to numerous Lean consulting firms, educational organizations such as Harvard and Stanford, and even on humanitarian missions across Asia and Africa. With nearly 40 years of Lean experience, he has assisted over 450 companies. These include TPS projects in environments ranging from schools, hospitals, military organizations, and many others, across various countries including China, Mexico, Canada, Indonesia, Brazil, Japan, Austria, Lithuania, Russia, the United Kingdom, and the United States.

With a Master’s degree in Technology Management, he is a faculty member of the Lean Enterprise Institute (LEI) and an instructor of Global Strategy Management for the California Community College system. He is a Lean speaker for graduate classes at Stanford University, the University of Southern California, La Verne, and San Diego State University.

Darril wilburn

While at Toyota, Darril studied the Toyota Production System as a member of the OMDD, Toyota’s internal group of Sensei.

He also developed and implemented the Toyota Way 2001 at Toyota’s largest manufacturing plant in North America and worked with the Toyota Institute in Japan to implement the Toyota Business Practice (TBP), leading the global pilot of this program as well as the North American Senior Executive Sessions.

As a consultant, he’s had the opportunity to work with over 100 companies in countries such as the United States, Brazil, Indonesia, Germany, the Czech Republic, Poland, and Lithuania, among others. Darril is also an active speaker, delivering presentations and lectures on Lean Principles worldwide.

EDSON NAGAMACHI

Edson worked for 30 years at Toyota do Brasil and Toyota Mercosur in Project Management, Industrial Operations, and Production Engineering, holding various positions such as Director of Innovation and Industry 4.0, Production Director, Plant Director, and Project Leader in flow and process design.

Throughout his career as a Toyota executive, he led projects and technology transfer initiatives on-site at various Toyota plants beyond the four Brazilian factories, including Toyota facilities in Argentina, Venezuela, Texas, Kentucky, Poland, Thailand, India, and Japan.

He holds a degree in Metallurgical Engineering from the Polytechnic School of USP and a specialization in Business Administration from EAESP – Fundação Getúlio Vargas.

SÉRGIO NIYAMA

Sérgio spent almost 35 years working at Toyota, starting in 1986 at the São Bernardo do Campo plant, where the Bandeirante Jeep was produced, considered the first Toyota plant outside of Japan.

During his professional career, he had the opportunity to participate in global Toyota meetings around the world, bringing best practices.

He held the position of Vice President of Production at Toyota do Brasil, responsible for the 4 plants, and was an executive advisor to the continuous improvement division.

He holds a degree in Metallurgical Engineering from FEI, with an extension course in materials at Akita University in Japan.

jim zehmer

President of Toyota Auto Body California (TABC) until 2024. Jim held several leadership positions, including Controller, General Manager of Production Support, and finally, President of TABC.

Under his leadership, TABC celebrated its 50th anniversary, marking a significant milestone for Toyota’s first plant in North America.

He supervised administrative functions at Toyota Motor Manufacturing in Baja California, Toyota’s vehicle assembly plant in Tijuana, Mexico.

He holds a degree in Economics from UCLA and an MBA in Corporate Finance from USC.

gerson damiani

Gerson Daminai worked for Toyota Brazil for 16 years in several production divisions, including casting, heat treatment, machining, assembly, and stamping.

He has extensive experience in TPS (Toyota Production System) and Quality Control Circles (QCC), and is currently assisting many companies in South America, Mexico, and the United States in optimizing their cost reduction processes.

He holds a degree in Mechanical Engineering and a postgraduate degree in Business Administration for Engineers.

THE ONLY LEAN TRAINING WITH DUAL INTERNATIONAL CERTIFICATION, ENTIRELY IN ENGLISH AND EXCLUSIVE FOR AMERICANS

The Lean Immersion Week is an Executive Lean training, unprecedented in USA, as it involves 7 days of immersive in-person training at San Diego State University (SDSU), one of the most renowned American universities, with the leading Lean experts of today, senseis with Toyota DNA.

The Lean Immersion Week is the only international Lean program exclusive in Portuguese and English, and with dual international certification: from San Diego State University (SDSU) and Honsha USA.

The Lean Immersion Week invests your time in teaching essential concepts and methodologies and in intense, rapid skill development through highly impactful and up-to-date simulations, exposing you to deep challenges and insights, so you can create new and long-lasting work models.

The Lean Immersion Week is the definitive Executive program because you will have access to a powerful methodology that will teach you how to think and act Lean within your organization, team, and market.

The Lean Immersion Week features renowned international experts who are driving major transformations in the largest companies in the USA and around the world, with exclusive access to the teachings and experiences that are generating real and immediate results.

The Lean Immersion Week updates your knowledge of the most efficient Lean strategies today and challenges your concepts about their application. It creates a solid foundation for understanding future scenarios and building Lean businesses and operations.

San Diego State University (SDSU) was founded in 1897 as San Diego School and is located in the Greater San Diego area, California.

It currently has over 34,000 students enrolled in undergraduate, master’s, and doctoral programs across various academic colleges, including: Arts and Letters, Business Administration, Education, Engineering, Health and Human Services, Sciences, Professional Studies, and Fine Arts.

SDSU is the oldest higher education institution in San Diego, with a unique location just 30 minutes north of the U.S.-Mexico border. Our community is fully committed to excellent teaching, meaningful research, and service to our regional community, as well as others we serve throughout the state, across the country, and internationally.

MEET THE TEAM BEHIND THE EVENT.

Honsha is a prominent Lean consulting group that has built a strong reputation by transforming companies through the implementation of the TPS/Lean philosophy practiced at Toyota. Based in San Diego, California (USA), with offices in São Paulo (Brazil) and Tokyo (Japan), Honsha serves companies of all sizes and types, ranging from small and medium-sized businesses to the Fortune 500 and large multinational corporations worldwide.

For nearly three decades, Honsha has been implementing TPS/Lean across various industries globally, including Automotive, Food, Pharmaceutical, Manufacturing, Healthcare, Banking, Insurance, Government, and more. We focus on the purpose of TPS/Lean and the principles of Continuous Improvement and Respect before seeking ways to implement tools. This has allowed us to develop a strong and loyal customer base, as this is the foundation for our clients to become self-sufficient.

Honsha associates, as former members of the Toyota team, have been deeply exposed to Toyota’s culture and its DNA. Due to this unique background, our understanding goes beyond the Lean Manufacturing tools learned from books. At Honsha, everyone has worked, lived, and rooted their practices and modeling of TPS/Lean. Our clients always remind us that “we see things differently,” and that is our differentiator.

Companies that trust Honsha.

FREQUENTLY ASKED QUESTIONS.

Will the event be in-person and in the USA?

The event will take place in person at the San Diego State University facilities, California, USA.

What is included and what is not included in the registration cost?

The package includes accommodations in a university dormitory at San Diego State University, with breakfast and lunch provided. Also included are: the welcome dinner, the closing ceremony dinner, airport transfers to the university, and transportation to the visited companies.

Dinners on other days, airfare, travel insurance, and any other costs not mentioned above are the responsibility of the participants.

Can I participate only online?

There will be no live online transmission of the event. As it is exclusive content, the event is 100% in-person.

Is there any special condition for groups?

Yes. Just get in touch with our sales team for special group discounts.

Who issues the certificate of completion?

Participants will receive 2 internationally recognized certificates:

- Certificate from San Diego State University

- Certificate from Honsha USA

Will there be any kind of assessment?

Yes. Throughout the workshops, participants will be encouraged to apply the knowledge gained to the reality of their organizations. Assessments will take place during the activities, and feedback will be given both individually and in groups.

Will I need a tourist, student, or business visa?

Yes. Any of these visas will be sufficient for participation in the event. For those who need a Letter of Invitation from San Diego State University to help expedite the visa process, just contact our sales team.

How many days do I have to cancel and request a refund?

Since it’s an online purchase, you have 7 days to cancel and receive an immediate refund.

For longer deadlines, we offer the option to pay a 30% deposit on the ticket price. Your spot will be reserved for up to 4 weeks before the event date, which is the final deadline for the remaining 70% payment. If you decide to cancel your spot, the deposit will not be refunded.

How will I know the locations and times of the activities?

All students will receive a Student Kit with all the information about locations, schedules, program details, contact and emergency numbers, as well as study materials.